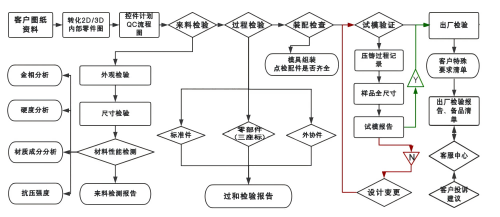

★ Demand Analysis: Clarify the customer's product requirements, including product dimensions, shapes, materials, functional requirements, and production volume. You can provide design drawings, sample photos, physical samples, etc.

★ Design Proposal: Based on customer requirements, conduct preliminary mold design, including 3D model creation, mold flow analysis, mold structural design, etc.

★ Material Selection: Assist customers in selecting appropriate mold materials according to the product's application environment and performance requirements.

★ Processing & Manufacturing: Use high-precision equipment such as CNC machines to process each mold component, ensuring mold precision and quality.

★ Assembly & Debugging: Assemble all mold components and conduct debugging to ensure that the mold functions properly.

★ Trial Run Verification: Conduct a trial run on the production line to verify whether the mold meets design requirements and whether the product meets the expected quality standards.

★ Delivery & After-sales Service: Deliver the mold to the customer upon acceptance and provide necessary technical support and after-sales service.