Product Description:

In the realm of central heating systems for urban and regional areas, control valves and gate valves play pivotal roles in ensuring efficient and reliable operation. These valves are engineered with precision, incorporating key components such as the valve body, bonnet, disc, stem, nut, and seat ring, each contributing to their overall functionality and performance.

The control valve is a critical element in central heating systems, designed primarily for the precise adjustment of flow volume. Its valve body serves as the main housing, providing structural integrity and housing the internal components. The bonnet, attached to the valve body, encloses the stem and other moving parts, protecting them from external elements.

At the heart of the control valve lies the disc, which moves linearly along the stem to regulate the flow of the heating medium. The stem, guided by the nut, ensures smooth and accurate movement of the disc, allowing for fine-tuned control over the flow rate. The seat ring, positioned at the valve's outlet, forms a tight seal with the disc when closed, preventing leakage and maintaining system pressure.

Control valves are particularly suitable for central heating systems where precise temperature control and energy efficiency are paramount. By adjusting the flow volume, these valves can respond dynamically to changes in heating demand, ensuring optimal comfort levels while minimizing energy consumption. Their ability to modulate flow also helps in balancing the system, preventing overheating or underheating in different zones.

Product details:

|

|

|

Product Parameters:

| Item Serial No. | 4-AGV-001 |

| Item Description | Adjustable Gate Valve |

| Manufacturing Process/Technique | Forging/Casting |

| Application Field | Petroleum, Chemical Industry, Power Industry, Mining Equipment, Construction, Water Supply System |

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Duplex Stainless Steel, Nickel-Based Alloys, Copper Alloys, Cast Iron |

| Dimensions | As per customer's requirement |

| Weight | based on the actual product manufactured |

| Surface Treatment | Polishing, Anti-corrosion treatment (Painting, Nickel plating), Thermal spraying, or as per customer's requirement |

| Marking | As per customer's requirement |

| Production Standard | As per customer's requirement |

| Terms of Price | Ex-work |

| Terms of Payment | T/T |

| Lead Time | In general, within 45 working days |

| Packaging Details | Wooden boxes, cartons or as per customer's requirement |

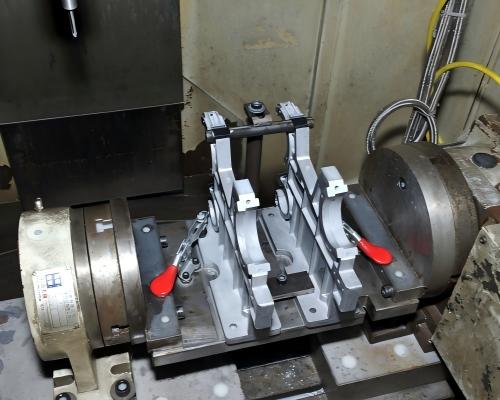

Production workshop

|

|

|

|

|

|

Packaging & shipping

All of our products are well packaged before leaving our warehouse. We offer different packaging options depending on the weight, size, and quantity of the products. Normally, paper boxes are used for small and light components, strengthened wooden boxes with steel frame are used for large and heavy components. To prevent damage to the products during shipment, some products are wrapped with plastic bags. Shipment normally takes 25-40 days by sea and 3-5 days by air.

|

|

|

|

|

|